Factory work might not be what you think. The days of a dingy, dark, and dangerous work atmosphere have changed in our area.

To highlight the growth of manufacturing jobs in our area and how "hands-on training" has changed for area students, Newswatch 16's Ryan Leckey teamed up with students and staff from Johnson College and Don's Machine Shop in West Pittston.

Johnson College is a trade and technical school based in Lackawanna County. It has expanded its learning environment to real-world companies to get students exposed to and trained more efficiently on various types of manufacturing work.

Johnson College and Don's Machine Shop have come together to design a curriculum for a course that gives students foundational principles needed to start working at a machine shop and have enough knowledge that they can make money for that machine shop.

The company in Luzerne County is teaching students everything from programming machines to the ins and outs of 3D printing.

One highlight tackled by Johnson College President Dr. Katie Leonard is the need for more women in manufacturing positions.

Dr. Leonard explained how these types of jobs can offer moms flexible schedules with pay ranging from $25 to $50 an hour.

As for the growth in manufacturing jobs in our area, there is a nonprofit organization that tracks that development. Northeastern Pennsylvania Industrial Resource Center focuses on the financial impact and evolvement of manufacturing jobs in NEPA. Click here to see a year in review.

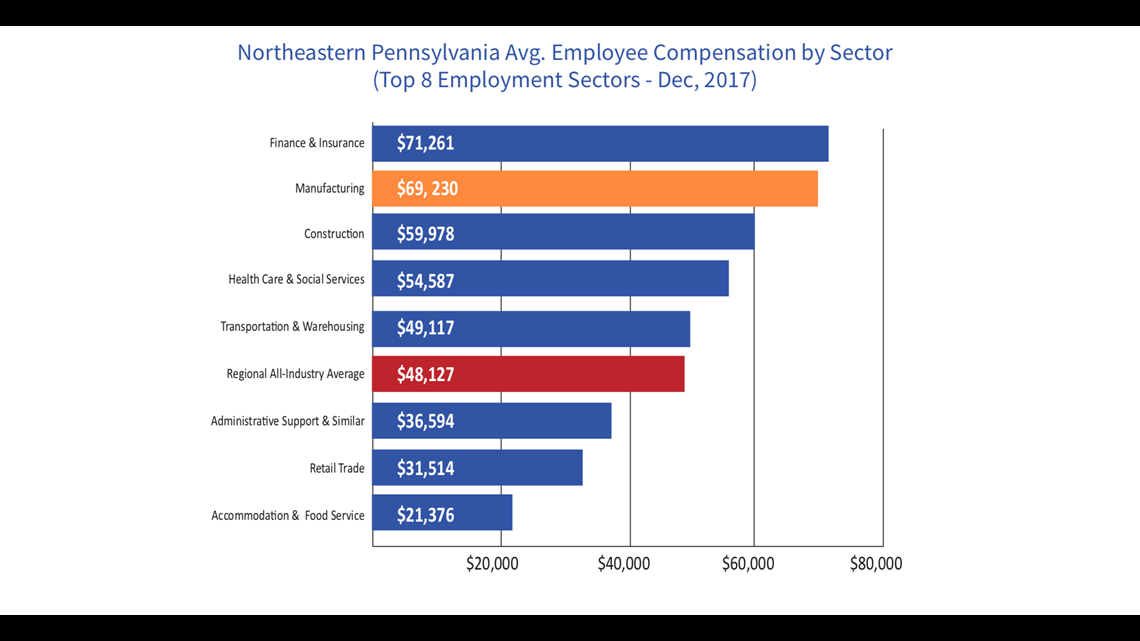

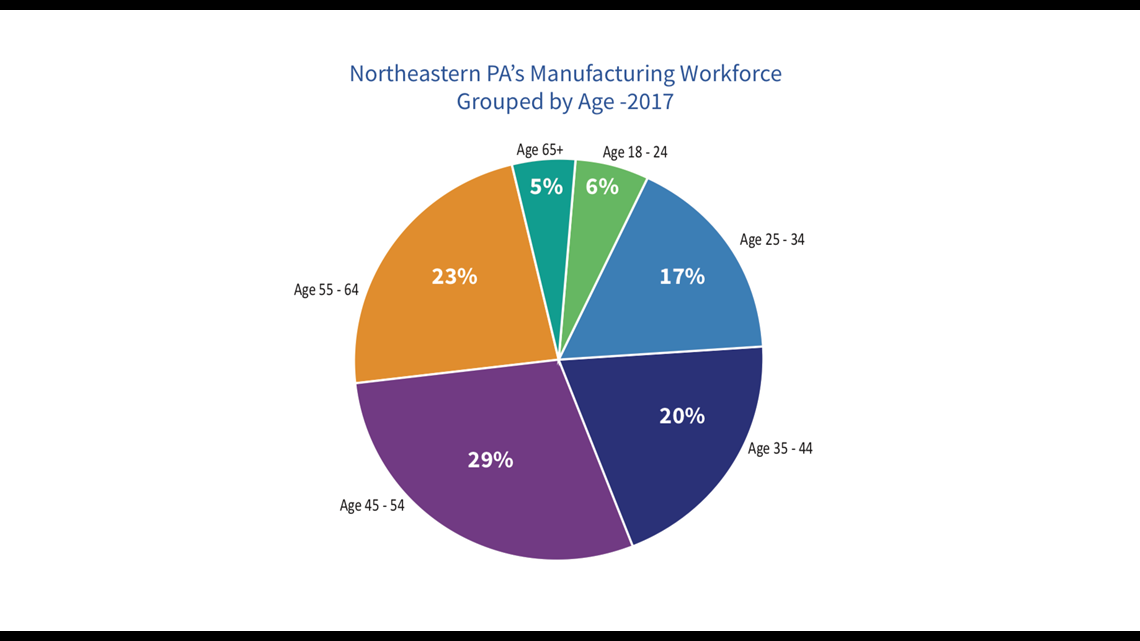

Some of the key elements from the nonprofit are highlighted in the charts below, including the need for the next generation of manufacturing employees.

The following statistics about the growth and demand for manufacturing jobs in our area have been provided by Johnson College:

- Across Lackawanna, Luzerne, Monroe, Pike, and Wayne counties – an area home to over 280,000 workers spread across 19 different private sector industries – manufacturing leads the pack in terms of job count, average annual employee compensation paid and total annual compensation infused into the regional economy

- Hourly wage – Between $50 - $25 per hour

- Number of Jobs in the field: 561,000 manufacturing jobs in the state of PA,

- 28,000 in the Scranton & Wilkes-Barre Area (According to BLS Sept. 2019)

- Providing approximately 1 out of every 9 area jobs

- The average manufacturing worker earns a level of annual compensation that is 44% above the overall regional average

- Manufacturers are creating jobs at a rate far outpacing that of their national counterparts

- Industrial employment is expanding in key high-tech and high-pay industrial sub-sectors, such as advanced plastics, electronics, and specialty fabricated metal products

- Johnson College AMT program, click here.

- In the transition to more technology-driven sectors, total manufacturing worker compensation increased every year from 2013 to 2017

- Manufacturing provides an abundance of high-tech, family-sustaining jobs

- In 2017, northeastern PA’s 734 manufacturing firms provided over $2.1 billion in total compensation to their workers

- Continuous improvement techniques, commonly referred to as Lean Manufacturing, aim to improve productivity, reduce operating costs, eliminate waste, and create internal capacity to pursue innovation, new products, and new market opportunities.

- Attracting & retaining workers

- Many local manufacturing companies are turning to engagement with high schools, technical schools, colleges, and universities to attract talent and discuss career opportunities

- DON’S MACHINE SHOP – Modified their space into a classroom to teach the new generation and expose people to the possibilities

- This company brought training in house to fill a need with Johnson College’s help

- Environment

- Local firms are also modifying their facilities, updating benefit plans, and stepping away from the tired workplace models in order to hire a new generation.

- JC NEW LAB SPACE – Replicates the feel of General Dynamics, Lockheed Martin and other manufacturers – no longer dingy, dark environment

- Dr. Leonard and administration have taken many industry tours and visits to align its teaching space with the real-world feel of manufacturing facilities